Technical Committee QPA

General Information

Deputy Chair: Dr Hwa Kian CHAI

Cluster C

Subject matter

Additive manufacturing or contour crafting in concrete structure construction, namely 3D printing of cementitious composite materials has the potential to revolutionize the traditional construction methods by permitting the creation of complex architectural designs, reducing material wastage, and speeding up construction processes. Significant aspects of the state-of-theart studies in 3D printing of concrete include materials, printing technologies, structural integrity and durability, and design possibilities. For studies on materials, discussions have been revolving around the types of cementitious materials suitable for 3D printing, including high performance cement-based mixes and advanced additives for improving workability and strength, and the utilizations of sustainable alternatives including recycled cement/ aggregates and geopolymers. In the case for printing technologies, reports are found detailing developments of various printing techniques such as extrusion-based methods, powderbased methods, and binder jetting, which focus on discussing advantages, limitations, and applications of the respective methods in real-world construction. Research has also been focused on optimizing the structural integrity and durability of 3D printed structures with cementitious composites. This includes exploring reinforcement strategies, curing methods, and post-processing treatments to enhance structural performance and longevity of different structural systems printed with cementitious composites. In terms of study for design possibilities, the ability to create complex geometries and custom designs has been a major focus. Numerous reports have showcased examples of architectural innovations that leverage 3D printing of cementitious composites, including enabling intricate shapes and structures that were previously challenging or impossible to construct using traditional methods.

As mentioned previously, in the last decade or so studies on 3D printing of concrete or cementitious composite materials have been focusing on addressing the fundamental but essentials aspects such as materials, mix design and printing process. In situations where buildings and civil infrastructure are constructed in an ideal manner following well-executed 3D printing processes, the optimally designed-and-built structures would require much less labor time and budget than the “traditionally built” ones in construction, leading to contributing to environmental-friendly infrastructure system. However, in cases where construction quality and structural performance levels are not sustained throughout the service life due to initial defects and unexpected degradation process, which may have been induced during the construction phase, premature failures, which have not been accounted in design, will cause disastrous consequences to lives and properties. In order to mitigate unanticipated failures caused by inherent structural faults of 3D printed structures, and to ensure their long-term performance and safety, quality assurance of additively manufactured materials namely different types of cementitious composites at the initial phase of casting (printing) and setting forms the principal scope of study. As they differ from the conventional cementitious composites in certain key properties, the 3D-printable ones are normally associated with layered deposition of materials through specialized printing system, the process of which introduces additional complexity and challenges in ensuring integrity of the layered materials on long term basis and subsequent impact to structural performance. Therefore, robust inspection and evaluation methods for initial quality control of these structures, and for continuous assurance of their long-term service performance are highly sought after. The inspection and evaluation methods should be developed and standardized to adapt with the stringent criteria for laboratory investigations and in-situ applications, respectively.

In the past RILEM TC activities, damage identification methods for concrete and masonry structures have successfully been studied and proposed through TC212-ACD (Acoustic emission and related NDE techniques for crack detection and damage evaluation in concrete). Following that, in TC239-MCM committee (On-site measurement of concrete and masonry structures by visualized NDT), on-site NDT-utilized damage visualization techniques have comprehensively been studied, focusing on establishment of reliable interpretation procedure of the results measured by non-destructive testing (NDT), which has been summarized as a state-of-the-art report at present. The resultant three RILEM recommendations from this TC led to 2 establishments of three ISO standards, namely 16836, 16837, and 16838 in 2019. In the follow up technical committee TC269-IAM (Damage assessment in consideration of repair/ retrofit-recovery in concrete and masonry structures by means of innovative NDT), a state-of-the-art report has been issued, with two RILEM recommendations submitted for review, which account for active/ passive elastic wave technologies for infrastructure assessment will be published. With reference to the extensive outcomes yielded from our three past TC activities, great contributions have been made in qualifying and quantifying damage in concrete and masonry structures capitalising on innovations realised for the various advanced NDT techniques that are applicable onsite.

Again, as additively manufactured structures with cementitious composites are usually prepared with layer-by-layer casting, effective methods should be developed for inspecting and evaluating casting quality, especially on ensuring soundness and homogeneity of the layered materials, and their long-term service performance., and in this regard it is considered that suitable NDT methods can be adapted in accounting for the different characteristics of laminar or layers and the forming of bulk materials, to enable effective characterization of the manufacturing quality, which subsequently leading towards ensuring long-term performance of the printed structure. In addition, the aforementioned RILEM TCs’ past activities which addressed the use of cutting-edge NDT methods to evaluate concrete and masonry (rocks and bricks) structures will surely lay the foundations that will complement and contribute to resolving the issues pertinent to quality and performance assurance of 3D printed structures using cementitious composites, and potentially those made with other types of additively manufactured materials. The outcome of this proposed technical committee is timely and will impact positively not only the concrete design and construction community, but potentially initiates significant revolution in sensing and health monitoring technology of relevant infrastructure sectors in near future. Under the proposed committee, suitable methodologies will be developed and proposed for testing, inspection and evaluation of additively manufactured structures using cementitious composites, suitable for both the laboratory investigation settings and in-situ application phases. In synchronising with the previous outcomes generated from past TCs, several RILEM recommendations, aiming at future adaptation to ISO standards, will be made based on the findings of this new TC.

Terms of reference

In the previous TC239-MCM, damage visualization procedures for in-situ structures were systemized by several promising NDT techniques namely AE Tomography, Radar, Thermography, and Impact Acoustics. Damage that is present inside concrete could be quantitatively assessed by the promising damage indices developed for the respective NDT methods. During the term of TC269-IAM, in-situ inspection methods using active and passive NDT techniques were proposed, followed by two RILEM recommendations which will be issued. In the newly proposed TC, namely ‘Damage evaluation of initial quality and performance of additively manufactured materials by cutting-edge NDT,’ we aim to work in tandem with existing RILEM TCs namely 303-PFC: Performance requirements and testing of fresh printable cement-based materials and 304-ADC: Assessment of Additively Manufactured Concrete Materials and Structures in exploring suitable methods for testing, inspecting and evaluating quality of 3D printed structures containing cementitious composites. Regular cross-TC meetings will be essential for discussing and identifying development gaps from the two parallel TCs that are related to application of NDTs for quality assurance and long term performance evaluation, including durability assessment. Collaborative work with these TCs will be emphasised through joint experimentation and onsite measurements, so data sharing and multi-faceted analysis become possible in increasing the feasibility and practicality of 3D printing of cementitious composites, which in turn would direct towards the development of suitable recommendations for researchers and practitioners in an attempt to rationalize 3D printing of concrete structures. Specifically, activities of the proposed TC will encompass series of studies on measurement instrumentation, data analysis and interpretation of the states of materials and structures subject to various forms of defects during their fabrication, and in different stages of their service period namely exposures to principal types of mechanical loading and weathering, capitalizing on innovations achieved through integrating the different contemporary NDT techniques including elastic wave methods, X-ray scanning, Tomography and laser Doppler-vibrometry. Effective combined use of these techniques offers multifaceted assessment, featuring visualization of internal defects and damage characterization informed by analysis of different parameters including wave dominant frequencies, density, travel time, attenuation, and structure vibration mode. For thin layered structures, the use of techniques such as Tera-Hz imaging, Thermography and Impact Acoustics will be studied. In addition, for casting phase the implementation of aggregate- or small stone-sized sensors will be studied to assess their feasibility for futuristic

applications. MEMS (Micro electromechanical systems) sensors in consideration of autonomous energy harvesting as well as data transmission will be examined. The proposed TC will also explore the use of machine learning to increase coherence and accuracy of data analysis for damage location prediction and severity classification, considered as a big step towards realising automated online assessment methodologies using NDT to mitigate possibility of flawed manufacturing. Finally, the findings of the proposed TC activity, including the NDT results and data analysis outcome, which are unavailable so far for the 3D concrete printing sector, will be summarized as a state-of-the-art report. The first testing standards of additively manufacture concrete, which can also be applied to stratum/ layered masonry/composites, not only for laboratory specimen level but also in-situ structural level will be proposed in the form of several RILEM recommendations. This will be followed by adaptation of these recommendations in the application and development of relevant ISO standards for initial quality and long-term performance evaluation of additively manufactured materials and structures.

Detailed working programme

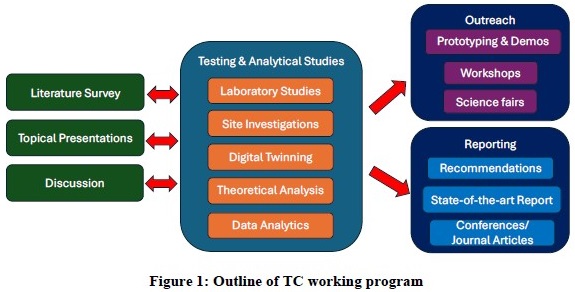

Figure 1 provides an overview of the working program for this proposed TC. The activities involved are described in more detail as follow:

- Literature Survey, Topical Presentations and Discussions

Through its members, the TC will engage in extensive literature survey to grasp the latest development in 3D printing technology for cementitious materials and composite based structures, focusing on identifying specific market needs and technical challenges for techniques that help ensure initial quality and facilitate long term performance prediction. This will provide useful insights to the TC in consolidate further the scope of its activities and specific deliverables. Besides, topical presentations by members and invited talks by prominent researchers of the field and industry representatives will form part of the regular activities in the TC meetings to promote continuous idea exchange and discussion of the relevant issues. Furthermore,joint meetings with TC303-PFC and TC304-ADC will also be arranged at regular intervals to facilitate information sharing and collaborative work.

- Testing and Analytical Studies

The testing and analytical studies planned for this TC will involve physical and numerical works aiming at developing practical methodologies for assessing quality and performance of 3D printed cementitious composite materials and structures using non-destructive testing techniques, emphasising on innovations implemented for the techniques given in Section 3 above. Specifically, the physical testing will be conducted on specimens and actual structures of various configurations in developing methodologies for instrumentation, data collection and analysis that suit different purposes. Sophisticated numerical investigations will be carried out in complimentary to physical testing to establish and validate the theoretical and analytical frameworks associated with the different NDT techniques, for instance in better understanding material behaviour and effects of material anisotropy and particle packing order on elastic wave propagation and vibration behaviour of material/ structure at different scales of application, and in developing quantitative relationships between NDT measured data with quality as well as performance of the printed structures. Extensive dataset obtained from digital twinning and physical experiments will be used for developing reliable machine learning (data analytics) schemes that are useful for refining data analysis and interpretation. Joint studies with TC303-PFC and TC304-ADC will be organised to ensure sufficient coverage of the current issues associated with realising quality and performance assurance of 3D printing at industry scales, the outcome of which will promptly inform appropriate onsite NDT instrumentation and data analysis for various types of cementitious composites. The collective effort will include joint experiments and data analysis by members of the three TCs.

- Outreach Activities

Throughout the duration of this TC, several symposia and workshops will be organized, purposed at providing a knowledge transfer platform for TC members to interact with the wider research community, industry and policy makers to share presentations and discussions of the TC´s findings. Experts who are not member of the TC will be invited to contribute in the workshops. Laboratory and onsite demonstrations will be held given the opportunity in collaboration with industry partners, to showcase practical implementation of the assessment methodologies developed by the TC. The TC members will find avenues to engage with exhibitions and science fairs as an initiative to inform the public and other stakeholders on the latest technology in 3D printing of cementitious composite structures and their assessment methods.

- Reporting

The results of the literature survey and discussions will be compiled as a state-of-the-art report by the proposed TC. The report will also contain relevant experience of the TC members and other research groups based on laboratory experiments and field work. Proceedings of the symposia and workshops (as part of the outreach activities) will be published as a special issue of Materials & Structures journal. Towards the end of evaluation and validation through a series of round-robin tests carried out by the TC members, recommendations for practice will be prepared in the form of standardized manuals. The recommendations will be submitted for review and publication in Materials & Structures journal. In addition, RILEM recommendation will be developed based on the TC findings, which could then be associated with CEN or ISO as a pre-standard.

- Literature (mainly derived from previous TC activities (TC 212-ACD, TC 239-MCM and TC 269-IAM)) with

knowledge and experience applicable to the proposed TC

1. Aggelis, G.D., T. Shiotani (2007) Experimental study of surface wave propagation in strongly heterogeneous media, Journal of the Acoustical Society of America, 122(5), 151-157.

2. Aggelis, G.D., T. Shiotani (2008) Surface wave dispersion in cement-based media: inclusion size effect, NDT & E International, 41, 319-325.

3. Shiotani, T., Aggelis G.D. (2009) Wave propagation in cementitious material containing artificial distributed damage, Materials and Structures 42, 377-384.

4. Chai, H, S. Momoki, D.G. Aggelis, T. Shiotani (2010) Characterization of deep surface-opening cracks in concrete, ACI Materials Journal, Vol. 107, No. 3, 305-311.

5. Aggelis, D.G., N. Tsimpris, H.K. Chai, T. Shiotani, Y. Kobayashi (2011) Numerical simulation of elastic waves for visualization of defects, Construction and Building Materials, 25, 1503-1512.

6. Kawasaki, Y., T. Wakuda, T. Kobarai, M. Ohtsu (2013) Corrosion mechanisms in reinforced concrete by acoustic emission, Construction and Building Materials, Vol.48, 1240-1247.

7. Aggelis, D.G., A.C. Mpalaskas, T.E. MATIKAS (2013) Investigation of different fracture modes in cement-based materials by acoustic emission. Cement and Concrete Research, 48: 1-8.

8. Carpinteri, A., G. Lacidogna, F.Accornero, A.C. Mpalaskas, T.E. Matikas, D.G. Aggelis (2013) Influence of damage in the acoustic emission parameters. Cement and Concrete Composites, 44: 9-16.

9. Kawasaki, Y., S. Wasada, T. Okamoto, K. Izuno (2014) Evaluation for RC specimen damaged from rebar corrosion by acoustic emission technique, Construction and Building Materials,, Vol. 67, 157-164.

10. Farhidzadeh, A., A.C. Mpalaskas, T.E. Matikas, H.Farhidzadeh, D.G. Aggelis (2014) Fracture mode identification in cementitious materials using supervised pattern recognition of acoustic emission features. Construction and building materials, 67: 129-138.

11. Mpalaskas, A.C., O.V. Thanasia, T.E. Matikas, D.G. Aggelis (2014) Mechanical and fracture behavior of cement-based materials characterized by combined elastic wave approaches. Construction and Building Materials, 50: 649-656.

12. Takamine, H., K. Watabe, H. Miyata, H. Asaue, T. Nishida, T. Shiotani (2018) Efficient damage inspection of deteriorated RC bridge deck with rain-induced elastic wave, Construction and Building Materials, Vol. 162, 908-913

13. Watabe, K., H. Takamine, T. Nishida, T. Shiotani (2018) Novel non-destructive technique of internal deterioration in concrete deck with elastic wave approaches, Asset Intelligence through Integration and Interoperability and Contemporary Vibration Engineering Technologies, 665-676.

14. Nishijo, K., M. Ohno, T. Ishida (2019) Quantitative evaluation of buildability in 3D concrete printing based on shear vane test, Proc. of East Asaa-Pacific Conference on Structural Engineering & Construction (EASEC16).

15. Hashimoto, K., T. Shiotani, H. Mitsuya, K. C. Chang (2020) MEMS vibrational power generator for bridge slab and pier health monitoring, Applied Sciences 10 (22), Article 8198.

16. Czarnecki, S., Ł. Sadowski, J. Hoła (2021) Evaluation of interlayer bonding in layered composites based on non-destructive measurements and machine learning: Comparative analysis of selected learning algorithms, Automation in Construction, Vol. 132, 103977

17. Watanabe, T., A. Nouchi, S. Fujimoto, C. Hashimoto (2021) Evaluation of concrete strength and defects in concrete by elastic wave methods, Bridge Maintenance, Safty, Management, Life-Cycle Sustainability and Innovations, 509.

18. Kawasaki, Y., S. Fukui, T. Fukuyama (2022) Phenomenological process of rebar corrosion in reinforced concrete evaluated by acoustic emission and electrochemical noise, Construction and Building Materials, Vol.352, No. 17,128829.

19. Hashimoto, K., T. Shiotani (2022) Induction and amplification of elastic wave into cementitious material by applied laser ablation technique, Developments in the Built Environment 12 (2022) 100099.

20. Nishijo, K., Ohno, M., Ishida, T. (2022). Development of Cementitious Metamaterial with Compressive Strain Hardening Characteristics, Third RILEM International Conference on Concrete and Digital Fabrication. DC 2022. RILEM Bookseries, vol 37. Springer, Cham.

21. Czarnecki, S., Ł. Sadowski (2022) Morphological properties of the cement skin: Understanding the effect of contact with formwork, Case Studies in Construction Materials, Volume 16, e01007.

22. Oguraa, N., Y. Konishi, S, Artur, T.Shiotani (2023) Monitoring of repaired water leaks using surface wave tomography, Developments in the Built Environment 14, 100133.

23. Hashimoto, K., T. Shiotani (2023) Sonic IR imaging technique for detection of crack interfaces in cementitious materials, Construction and Building Materials, 386, 131549.

24. Ohno, M., M. Pierre, K. Imagawaa, T. Ishida (2023) Simulation and learning-driven design for architected cement-based materials, Journal of Building Engineering, 65, 105768.

25. Artur, S., N. Ogura, T. Shiotani (2023) Application of elastic wave tomography method for damage evaluation in a large-scale reinforced concrete structure, Developments in the Built Environment 14, 100127

26. Watanabe,T., A. Nouchi, S. Namerikawa, C. Hashimoto (2023) Evaluation of condition on replacing repaired concrete based on NDT and mahalanobis-taguchi system, Frontiers in Built Environment, Non-Destructive Evaluation of Building Materials for Sustainable Future, 2023.

27. Navarrete, I., M. Lopez, Y. Kurama (2021) Multi-layer casting of self-consolidating concrete: Influence of mortar rheology and casting parameters on the inter-layer bond strength, Construction and Building Materials, 303, 124492.

28. Rahemipoor, S., M. Hasany, M. Mehrali, K. Almdal, N. Ranjbar, M. Mehrali (2023) Phase change materials incorporation into 3D printed geopolymer cement: A sustainable approach to enhance the comfort and energy efficiency of buildings, Journal of Cleaner Production, 417, 138005.

Technical environment

This TC is proposed as a suitable successor to TC 212-ACD, TC 239-MCM and TC 269-IAM which had addressed successfully development and application of cutting-edge NDT techniques for assessment of masonry and concrete structures. The proposed TC is strategic and timely, which will link well to two existing TCs namely TC 303-PFC (Cluster A- Material processing and characterization): “Performance requirements and testing of fresh printable cement-based materials” and TC 304-ADC (Cluster A): in providing innovative solutions for assessing quality and performance of 3D printed cementitious composites that complement the activities of the said two TCs. Besides, the proposed TC can adapt its activities to effectively connect with any other TCs that have aims to address concrete performance evaluation and quantification, such as TC 287-CCS and TC 289-DCM. Outside RILEM, close working relations can be established with ACI Committee 228, European Working Group on Acoustic Emission (EWGAE), Acoustic Emission Working Group (AEWG)(USA), AE technical committee of JSNDI and IIIAE (International Institute of Innovative Acoustic Emission), owing to the chairmen of these committees being key members of the proposed TC. Also, the Chair of the proposed TC will gain excellent opportunity to work with the Chair of ISO TC-135 (Non-Destructive Testing), Dr. Ogata (formerly president of JSNDI); the latter previously played an instrumental role in helping the former develop proposals for three ISO standards on the use of AE technique for concrete materials and structures, based on the recommendations resulted from the activities of the past TCs which the former was involved with (TC 212-ACD, TC 239-MCM and TC 269-IAM). It should also be noted that the activities for the proposed TC will be financially supported in part by a Japanese science funding scheme, namely Cross-ministerial Strategic Innovation Promotion Program (SIP). All findings obtained from the activities of the SIP will also be conveniently available to support the endeavor of the proposed TC, in enabling the realization of practical and beneficial outcomes as described above.

Expected achievements

The following achievements are promisingly expected, which can be attained based on our immense experience from the past closely related TC activities:

- RILEM recommendations and recommended practices for quality assurance and performance assessment of 3D printed cementitious composites using innovative NDT instrumentation and data analysis;

- Dataset obtained from independent and collaborative (with other TCs) laboratory testing and onsite measurements;

- Workshop proceedings, possibly published as special issues of Materials & Structures journal;

- State-of-the-art report for assuring initial quality and long-term performance of 3D printed structures using different types of cementitious composites based on application of innovative NDT methodologies

- Pre-standards for the relevant assessment methods and data analysis schemes to be submitted to ISO.

Group of users

Testing laboratories, Owners of infrastructure, Construction companies, Structural assessment specialists, Research institutes and Universities.

Specific use of the results

Effective quality control and long-term performance assessment of 3D printed cementitious composite structures are keyenablers to realizing mass application of the technology. The outcomes of the proposed TC will provide standardized methodologies on the use of non-destructive testing protocols for inspection, evaluation and assessment of 3D printed cementitious composite structures at the initial casting phase, which can also be adapted for fixed-interval monitoring purposes during the structure’s service lifetime. Working together with other existing TCs that share common interests, the proposed TC will help achieve a significant step towards accelerating widespread adoption of 3D printing technology for cementitious composite construction, which shall bring forth significant impacts in various economic aspects:

1) Reduced Labor Costs: One of the primary advantages of 3D printing in construction is the potential for reduced labor costs. Automation through 3D printing minimizes the need for manual labor in certain construction tasks, leading to savings in wages and related expenses; 2) Faster Construction Speed: 3D printing technology has the potential to accelerate the construction process significantly. Complex structures that might traditionally take months to build could be completed in a fraction of the time. This speed could lead to cost savings due to shorter project durations and reduced overheads; 3) Material Saving: compared to traditional construction methods, 3D printing of cementitious composites can achieve precise control of material consumption, minimizes waste output. The higher efficiency in material usage can lead to cost savings in the long term, especially considering the rising costs of raw materials. This also helps enable the reduction of carbon emission and energy consumption associated with raw material production and construction, contributing towards achieving net-zero practices; 4) Design Flexibility and Customizability: The flexibility of 3D printing allows for intricate and customized designs that would have been challenging or impossible to achieve with the traditional construction methods. The versatility can lead to fulfilment of stringent needs imposed by bespoke architectural designs that emphasise on both aesthetic and structural efficiency aspects; 5) Highly skilled Job Creation and Development: While communizing 3D printing technology might reduce the need for traditional construction jobs, it will create new roles that require specialized skills related to programming, operating and maintaining 3D printing facility. This opens up new opportunities for skill development in the relevant areas of emerging technologies; 6) Sustainable Infrastructure and Urban Development: The efficiency and cost-effectiveness of 3D printing technology in construction will become key driver for infrastructure development in areas that are deemed economically unfeasible with the existing construction technology. This help to stimulate economic growth in these areas and promote urbanisation in meeting the requirements of a safe and liveable built environment.