Technical Committee MBB

General Information

Deputy Chair: Yassin DA GLORIA

Cluster C

Subject matter

The use of eco-materials derived from agricultural products is an increasingly popular solution in the construction industry. The term "bio-aggregates" specifies the eco-materials derived from agricultural products used in the concrete, providing clarity on the subject matter. Several studies have been carried out on different agricultural resources, providing a range of information on the properties of plant aggregates and plant based concrete. However, predicting the mechanical behaviour of plant based concrete remains complex due to the various factors that influence this behaviour. It is therefore essential to bring together a wide range of different information scattered in the literature on the properties of plant aggregates, the properties of mineral matrices and their association with composites.

The proposal to set up a new technical committee should lead to the drafting of recommendations for rigorous and precise protocols to describe the mechanical behaviour and properties of plant-aggregate-based-concrete under different loads (compression, flexure and shear) as a function of the vegetal aggregates and the different mineral binders.

An initial literature review was carried out based on the compilation of 18 plant aggregates of different origins used in vegetal based concretes. The variability of the approaches used by the authors is significant and prevents a true intrinsic comparison of the materials. Several factors can influence the mechanical behaviour of vegetal concrete at the composite scale, such as the formulation, the moulding process (energy), the curing conditions, the morphology of the aggregates, the density, the porosity, the properties of the mineral matrix and the physico-chemical aggregate/matrix interactions. Consequently, the ultimate aim of our committee will be to unify the way in which the mechanical properties of bio-concrete are measured, based on the various factors that influence this mechanical behaviour.

Moreover it’s worth to mention that Common standards for conventional concrete are not fully applicable to bio-aggregate-based concrete due to several unique characteristics of bio-materials:

- Variability in Aggregate Properties: Bio-aggregates such as hemp, rice husk, and others have distinct physical and chemical properties that differ significantly from traditional mineral aggregates.

- Non-linear Mechanical Behaviour: The mechanical behaviour of bio-aggregate-based concrete, including factors like Young's modulus and shear modulus, is highly non-linear and influenced by the organic nature of the aggregates.

- Environmental Interaction: Bio-based materials interact differently with environmental conditions such as humidity and temperature, affecting their mechanical properties over time.

- Determinations of constitutive laws : The traditional laws applied for predicting the behaviour and properties of ordinary cement-based elements and systems cannot be applied in the case of bio-aggregate-based concrete.

Terms of reference

The proposed TC will deal with bio-based aggregates building materials subjected to compressive loading and will have a duration of 4 years.

This TC aims to bring together RILEM members from universities and research institutes. Considering the experience of TCs 236-BBM and 275- HDB, potential members are expected from Europe, South America. New members from sub-Saharan Africa are also targeted for the TC. PhD students and young researchers (under 35) will be involved through specific programmes.

The main work will be round robin tests with prefabricated hemp concrete samples. Prior to this, a bibliographic review of the procedure for performing the compression tests and obtaining the Young's modulus will be carried out.

The main topics of this TC are

1) To describe the compressive/flexural/shear behaviour of bio-based building materials (BBM) produced with different types of aggregates.

2) To propose a new protocol for performing compressive/flexural/shear tests

3) To propose a new procedure to obtain the Young's modulus, Poisson Coefficient and shear modulus.

3) To propose relationships to correlate the main properties with the aim of numerical modelling.

Detailed working programme

Work packages are as follows:

WP 0) A bibliographic review of the procedure for performing compression, flexural and tensile tests and obtaining Young's and shear modulus will be conducted. Standard methods for sample preparation will be analysed. Various techniques for measuring deformation will be compared. Factors affecting the accuracy of results will be identified. Finally, methods for calculating Young's and shear modulus will be examined to determine the most appropriate one.

WP 1) Description and test protocols of BBM compressive/flexural/shear behaviour

Compressive strength is one of the most important mechanical parameters of construction materials, indicating the ability of a material to withstand compressive loads without changing its shape or form or failing (Jami et al., 2019). To date, there is no established standard procedure for measuring or identifying compressive strength for compaction behaviour (Mazhoud et al., 2017; Niyigena, 2016; Walker et al., 2014). In fact, different names have been given to the method used to determine compressive strength.

The flexural behaviour of plant-based concrete has been characterised using three-point bending tests. In the literature, a number of studies have addressed the behaviour and flexural strength of plant- and soil-based materials (Acikel, n.d.; Belhadj et al., 2016; Chen et al., 2017; Elfordy et al, 2008; Garikapati and Sadeghian, 2020; Khazma et al, 2008; Laborel-Préneron et al, 2017; Mazhoud et al, 2017; Morsy, 2011; Murphy et al, n.d.; Nguyen, 2010; Sassoni et al, 2014; Sassu et al, 2016; Walker et al, 2014).

These studies show a wide variety of protocols, both in terms of sample size and the way the tests are performed, making it impossible to really understand how to rigorously interpret bending behaviour.

Since one of the most common types of failure in walls is shear, it is essential to understand the shear behaviour of plant concrete (Chabannes et al., 2017; Jami et al., 2019). In the literature, the shear behaviour of plant concretes has been investigated using triaxial compression tests. Only a few studies have investigated the shear behaviour of plant concrete (Chabannes et al., 2017; Youssef et al., 2015). More specifically, hemp concrete and rice husk concrete were the only two types of plant concrete tested in triaxial compression (Chabannes et al., 2017).

Objectives:

Based on the protocol of the previous Technical Committees 236-BBM and 275-HDB, we propose to harmonise the approaches to writing recommendations following a interlaboratory test on compressive/flexion/shear strength of vegetal concrete (Round Robin Test).

WP 2) Young’s/Shear modulus and Poisson factor determination

The modulus and Poisson factors values of plant-based concretes vary considerably in the literature. This variability stems from different parameters such as the nature of the constituents, the formulation, the casting process, the curing conditions and the method used to evaluate the modulus. In the latter case, (Niyigena et al., 2019, 2016) have demonstrated enormous variability in modulus values depending on the method used to calculate or assess the modulus. In fact, Young's modulus is not constant due to the strong non-linearity of the mechanical behaviour of plant concrete even in the elastic phase (Niyigena et al., 2016). To date, there is no conventional method or standard for calculating Young's modulus(Niyigena et al., 2019). Plant-based concretes can have several types of modulus depending on the type of compression test(Akkaoui et al., 2017; Mazhoud et al., 2017).

Objectives:

Based on WP1, a group will discuss the data from WP1 in order to assess the characteristics in a relevant way.

Technical environment

This TC will be a continuation of two previous TC’s focused on the bio-based buildings materials:

- 236-BBM: Bio-aggregates based building materials

- 275-HDB: Hygrothermal behaviour and Durability of Bio-aggregate based building materials

Expected achievements

The direct benefit of this TC is the establishment of an adequate protocol for determining the mechanical properties of the BBM’s, by taking into account the particularity of these unconventional materials. The results obtained from the TC will be essential for a better understood of the behaviour of such materials, then tools will be provide for a better dimensioning of construction elements or systems with the BBM’s.

The TC will produce review papers in a Topical Issue of Materials and Structure.

The progress of the activities will be discussed each two years during the ICBBM conference, which is the main international scientific event on the topic.

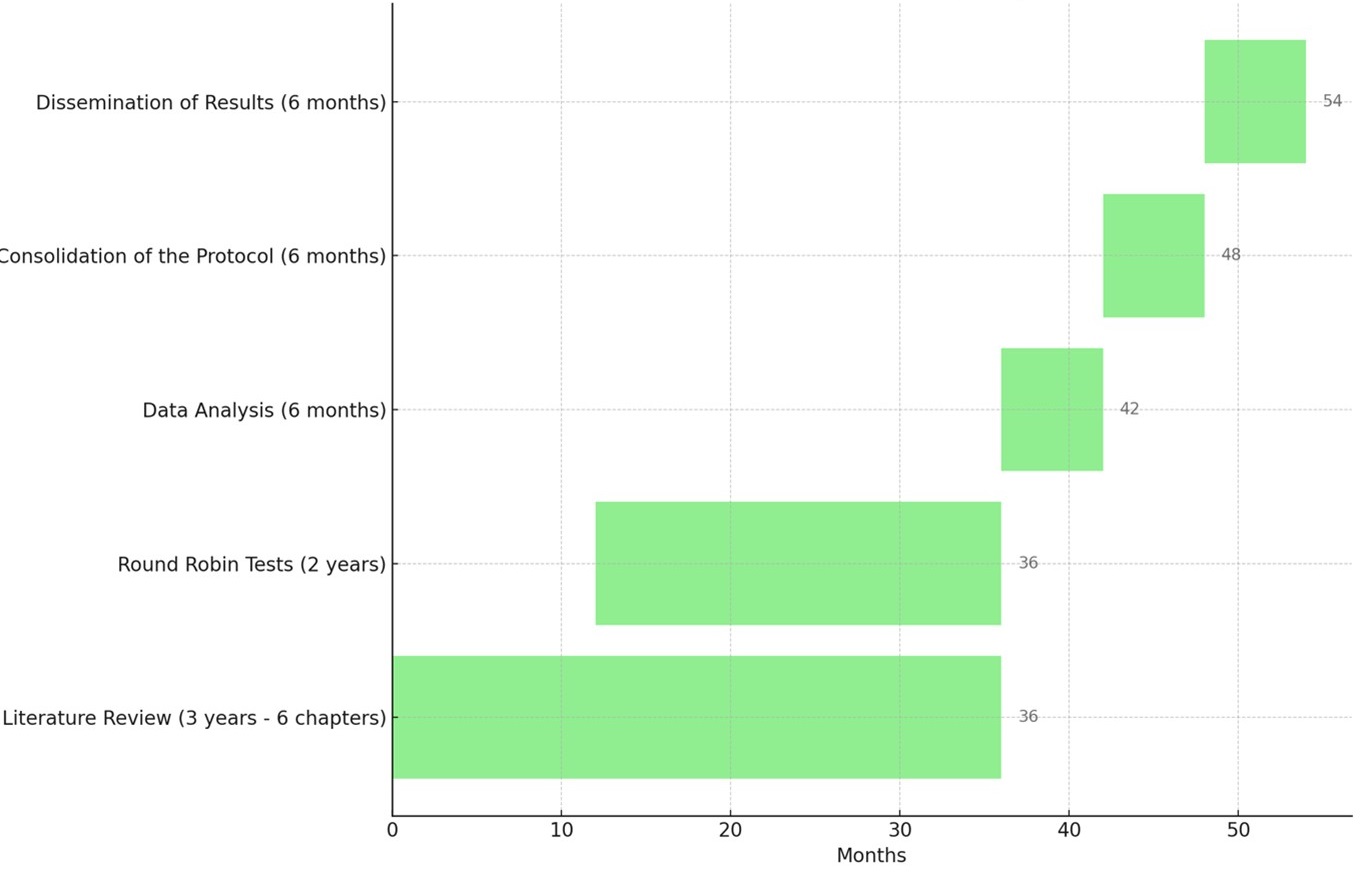

- Gantt Chart: A detailed Gantt chart outlining the timeline and milestones for the Technical Committee's activities is included. This chart cover the literature review, round robin tests, protocol development, data analysis, and dissemination of results over the proposed four-year duration.

Group of users

The targeted users are researchers, engineers and practitioners; Ph.D. students are also welcome to be directly involved in the activities of the TC.

Specific use of the results

- Usefulness: The anticipated usefulness of the results lies in the establishment of standardized protocols for measuring the mechanical properties of bio-aggregate-based concrete. This will provide a reliable basis for future research and application in construction, enhancing the performance and sustainability of bio-based building materials.

- Expected Impact: The expected impact includes both scientific and economic benefits. Scientifically, the standardization will lead to more consistent and comparable research outcomes, fostering further innovations. Economically, it will facilitate the broader adoption of eco-friendly materials in the construction industry, potentially reducing the carbon footprint and promoting sustainable building practices.